Printing a Cookbook

I went to see where Near & Far was being printed because, more than anything else, I was curious. I had an idea of what happens when a cookbook goes to the printer, a general concept of what it might be like, but at the end of the day, I really had no clue.

Settle in for a longer post than usual - this one covers some territory. I took a bit of a field trip a couple of weeks back. I went to see where my book was being printed because, more than anything else, I was curious. I had an idea of what happens when a cookbook goes to the printer, a general concept of what it might be like, but at the end of the day, I really had no clue. I spent twelve hours at a printer far from home, with a group of individuals who care deeply about how books are made, and I walked away with my understanding of the whole process flipped on its head. Let me start again. I thought I was flying to Hong Kong to see Near & Far "at the printer", but I now understand "printer" isn't the right term. I saw Near & Far at the bookmaker. Printing is just a fraction of what transpires in the final part of the bookmaking process.

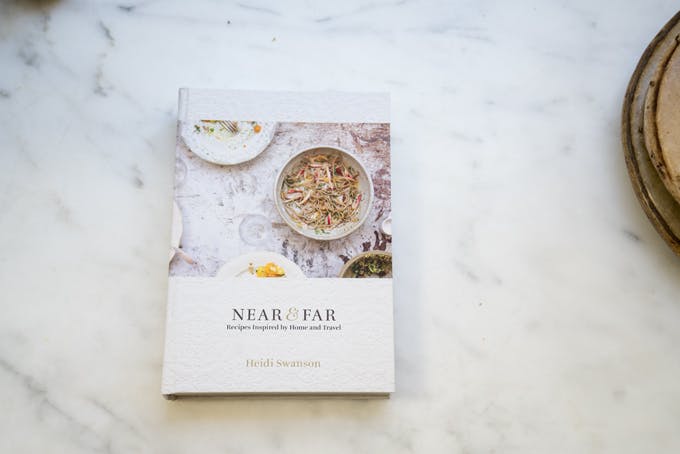

For those of you who are jumping in here, I've been writing, on occasion, about my process related to a cookbook I've been working on for the past few years: Near & Far: Recipes Inspired by Home and Travel. You can read other posts here, here, and here. I flew to Hong Kong with Serena Sigona, Senior Production Manager at Ten Speed Press to spend time at C & C Joint Printing Co. C & C is a historic (100+ year-old) printing company, known for being progressive on many fronts, and producing some of the best art, photography, cookbooks, and intricately designed titles available. On my radar: Polpo, The Andy Warhol Catalogue Raisonné, Christine Manfield's Tasting India, and Taschen's Palmeras. This is in addition to a lot of work they've done with smaller independent imprints producing beautiful, limited editions. I was excited to have Near & Far in their hands. They're known to be technically on point, creatively adventurous, and, when it comes producing highest quality, four-color, illustrated books, a dream partner.

So, let's talk more about making books. Each book has a different creation cycle. Mine started in the physical world - the ingredients, smells, and textures of my kitchen, the film and slides from my cameras, and the food on my table. It then evolved, and shape-shifted in different ways to exist in the computer world - Word files, TIFF photo files, everything in pixels, everything digitized. This is what I relay to Ten Speed Press, they work on the files, and eventually, over many months, the files are approved by author, publisher, and printer. I think the process starts to get hazy at this point for most authors. They've been working towards the date when their files are sent to the printer, it happens, and at some point (weeks or months later) an example of their finished book arrives in the mail. I was interested in understanding more about what goes on during that vague period, and I have to tell you, I was completely fascinated by what I saw.

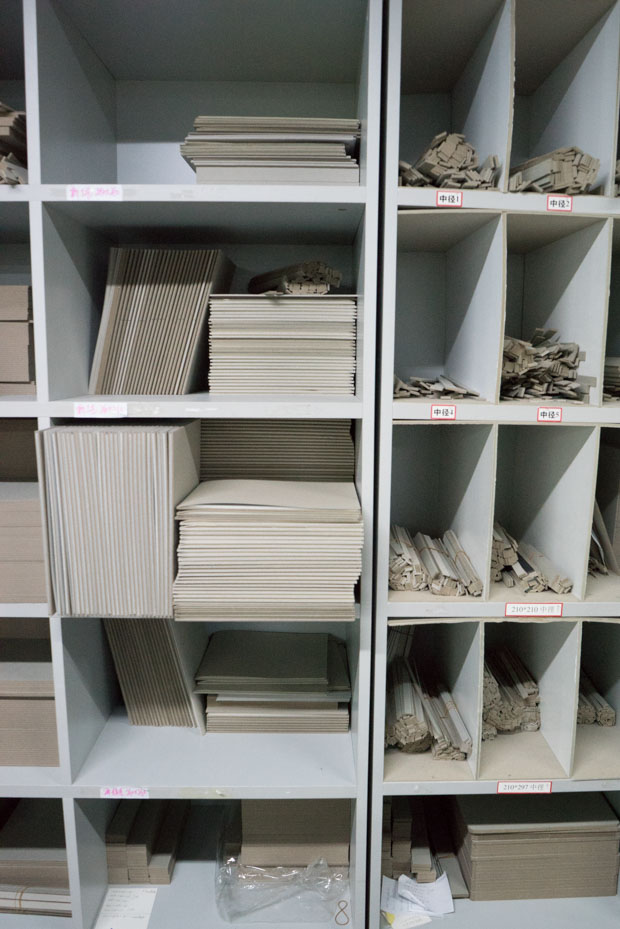

The amount of steps in the bookmaking process - the care, hand work, attention, experience needed, all of it was deeply humbling. People make these books - not giant machines, or factories. Skilled people. Yes, there are a bunch of crazy machines and tools in the process, but whether or not your book emerges as you imagined, is very much about the people, and the collaboration between the publisher, the place your book is made, and the individuals attending to each step. My book was in the binding process when I arrived. This means all sorts of things had already taken place, in different stages, and at different stations. For example: all of my pages had been proofed, printed, and trimmed. Take a look at the shot below. Those are the cover cases ready to receive the block of pages. But look more closely in the bottom left corner. You can see the way the cardboard has been cut into three pieces - front cover, back cover and spine. That happens at one station, those pieces are then wrapped and glued with the cover material at another station. My cover has a slight deboss texture, that happens at yet another station on another machine. So, as you walk around the floor, all the stations are working on different books at various stages in their production. I spied some INCREDIBLE books on deck for this Fall.

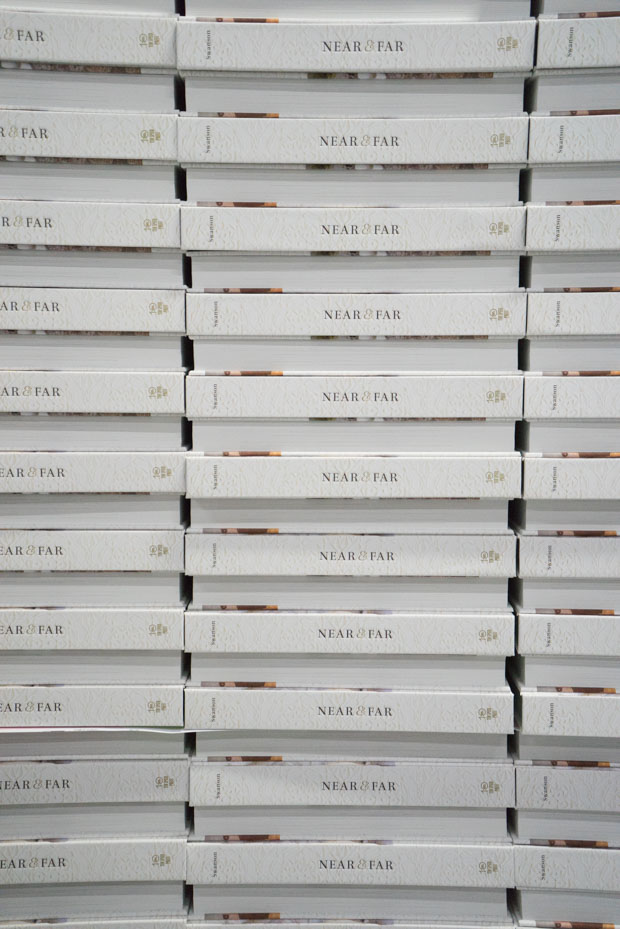

Cover cases stacked and ready to be fed into a hopper.

There were some fascinating machines to see. Over the course of the day a sampling of the machines I saw included: case maker machine, paper cutting machine (across the way from what must have been the world's largest blade sharpener), binding strength testing machine, paper folding machine, shipping container heat emulating machine, laminating machine, metallic press, die-cut making jigsaw, and on and on. Check out this machine below, it stitches the folded and stacked signatures (folded pages) together in preparation for the final binding process. If your book or project doesn't fit on one of the machines, for example, if it is too large or too small, it might be hand-stitched. Same thing goes for any step in the process - if you're only doing a small run of books, it might be produced almost entirely by hand.

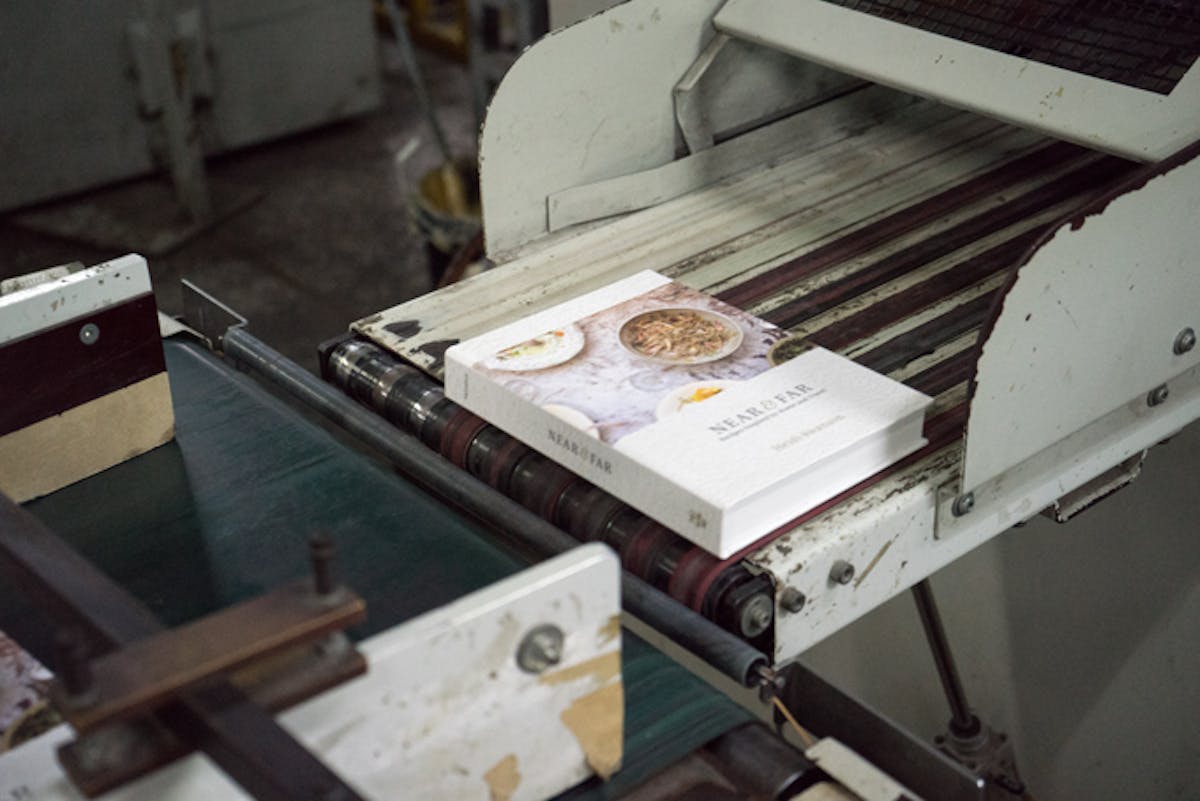

Below - the signatures have been folded, stitched and now glued together, and are here on a conveyer belt just before being paired with the aforementioned Near & Far cover cases.

I posted a short video of this stage - after the pairing of cover case and pages, the books emerge, are looked over, and are stacked on palettes. It's a real book!

Below - Paper samples. Authors are rarely involved in choosing where their books are printed. It's my understanding that publishers typically rely on a network of printers, often a combination of domestic and overseas. Some of the considerations are: ability of a printer to produce to a book's creative and technical specification, timeline for reprints, four color vs b/w (or one-color), cost, available paper stock, ability to get on a printer's schedule - it goes on and on. For example, below, you see a sampling of paper stocks. There is different paper availability at different printers, you want to be sure your paper will be available immediately if you need to do another print run.

Below - These are cover/case remnants. Early in any book process, publishers often request "dummy books" from the printer. These are one-of-a-kind "example" books made to a publisher's specification. It's a white book of whatever trim size you like, filled with blank pages of the paper you are considering. At C & C they're made, by hand, at a table of friendly ladies. The blank books are great to have because they give you a sense of what a finished book might feel like as a physical object, incredibly helpful. I've carried around a number of dummies for Near & Far over the past few years, and we've made tweaks to the paper weight and trim size because of it. And I can't resist the urge to fill the blank pages. So, these are materials used to make this sort of thing.

From the front of C & C - as far as scale goes - it reminded me, roughly, of a middle-sized American high school campus. There were the big press rooms, and then offices, workshops, canteen, storage, and a bunch of different task-specific neighborhoods.

Below - A floor plan map of C & C.

Below - On the factory floor, everyone brings a unique water bottle and keeps it on these shelves. To the right - you know the little bookmark ribbons? These are spools of remnant ribbon.

Remnant cover material. You know that canvas-like material that is often under a hardback book's paper cover? This is what it looks like before it is glued on the cardboard structure of the book.

Below - The big guns. This is one of (I think four?) big, offset presses at C & C. The new Heath Ceramics book was on this exact press at this exact moment, and it looked beautiful.

Below - covers being made.

Below - one of the workshops where some of the hand work happens. These were special covers being made for a small print run. If you look closely in the back, you can see a woman with an incredible wide brush used for gluing. I took a closer shot of it down below. I think I'd like to go back and just look more closely at all the amazing little tools, brushes, and devices that are used in their bookmaking process - so much of the work is very detailed and precise.

Below - One of the things that has always been important to me professionally is to be able to collaborate with individuals who are inspiring. I also tend to be friends with many of the people I work with over long periods of time, so I think about that as well. Nice, generous, easy to spend time with, curious - all important to me. This was my crew at C & C, and they checked all the boxes - Ken, Margaret, Viviana, Serena, (Me), Quenton. They were the best, and it meant a lot to me that they took so much time to share the details of their work with me. I hope I get to go back someday to understand the process even more, maybe on a future book. And I hope I have an opportunity to show them what I love about San Francisco at some point soon.

Near & Far Series:

- A New Cookbook

- Writing a Cookbook Proposal

- Making a Cookbook

- Printing a Cookbook (this post)

Post Your Comment

Comments

Hi, Heidi, I was recently gifted a copy of Near and Far. Gosh, I thoroughly enjoy it and have made several dishes our of your recipes. I hope you don’t mind me asking what kind of paper you use for the inner pages?

Wow, prior to college (back in the 80s) I worked in 2 book binderies and it’s amazing to see that the process is still being done exactly the same way I learned to do it all those years ago.

Absolutely fascinating! I hope to one day go through the process myself. Your new book looks so beautiful and I can’t wait for it to join your other two books on my carefully curated cookbook shelf.

hello heidi, i’ve finally had enough time to sit down and read this post about book printing/making. never had a chance to have a look at this process myself, and i can imagine it must been fascinating to you as an author! thanks for sharing and in the meantime I can’t wait to see the finished book in my hand! cx

Very very interesting, I wrote my book and send it to a local printer and I also had the previledge of seeing their machines. what you showed me is something I dream of building.

So excited to see your book in its final stage! Can’t wait to get it in my hands!

Utterly fascinating … best of luck with book sales!

So cool that you saw the whole process! Such a beautiful book!

hi heidi – love that you made this trip! makes us want to do it too. any chance you have pictures of our book on the press? best, r.

HS: Hi Robin – I’ll have a look through my files. I might have a shot or two of some of your pages on the light table next to the big press, but I was sensitive about not taking obvious shots of other people’s projects in process. Hope you’re well, and hope to run into you soon. -h

Wow. I love seeing the process that went into creating your beautiful book. And how exciting that you got the opportunity to see for yourself, makes it even more special! I love the picture of the book binding machine. I noticed that it is a Martini machine from Frauenfeld, Switzerland, just half an hour from where I am here in Germany. The company has a fascinating history, started out with the book binding machines in 1860 (that must be a very old machine!) and then began making cars between 1897 and 1934.

Wow… the process is really amazing to see! I guess you just take things for granted without having inside access like this. Been loving this series of posts and can’t wait for the book to come out! Congrats!

Thanks so much for sharing your trip to the printers with us Heidi! It is so rare to get this kind of insight and it is so fascinating to read about! I mentioned a few seeks ago how I had tried to buy your book on Amazon.co.uk but that the purchase was suddenly cancelled with the book no longer available on the site to order – not sure what the reason was for this hitch but just wanted to say the book is back on Amazon.co.uk and I have just pre-ordered it again!

Thank you for this wonderful in depth look at the bookmaking process. It is so inspiring to see all the untold hard work and technique that goes into creating the perfect book. x

how special! I am SO impressed with how much care and detail you put into how your books are designed. It absolutely shows. What a neat trip and thanks for sharing.

I used to work in corporate publications, and field trips to our printers were always one of my favorite parts of the job. As one of our printers once pointed out, every printing job is really a custom manufacturing job. Thanks for sharing these photos — it’s always wonderful to see people making beautiful objects with love and craft.

Your book is so beautiful! The entire process was so interesting to watch as it unfolded.

Yay!!! Time for a book party at Chandon! Let’s plan something. Email or call me and we can host something fun in Napa!!

I had no idea how much went into printing a book. Truly fascinating.

Such a fascinating look into the process. Best wishes for continued success!

Oh wow, great post here, Heidi! I’m really enjoying this Near & Far series, lots of info and inspiration. What a journey so far, indeed a labor of love!

Fascinating, Heidi! I really enjoyed reading this! As much as I love beautifully printed cookbooks, I also wasn’t aware of the process. It’s great to see the craftsmanship isn’t lost to machines. I am so excited for your next book, I cherish your other two and this one looks beautiful!

I’ve been following your blog for ten years now (time flies!) and love your photography/design sensibility, wholefood cooking style, and your uniquely engaging writing. You are an inspiration to me. Xx Liberty (Melbourne, Au)

So incredible to see this process; I never even thought about how cookbooks were printed! Thank you so much for sharing your findings! Also, I’m super excited to see your newest book. Can’t wait for it to join the Heidi collection on my bookshelf. 🙂

HS: Thanks Alanna! 🙂 Your site is looking amazing as ever. xx

This is a great post!! Thank you for posting them.

Where can I purchase this book? Can’t wait to keep one. 🙂

Thats is just amazing to see the complete process of your cookbook.

So many people involved in the printing process working with old machinery that still works! I can’t wait to read your book. Thanks for posting those pics of the printer company. So interesting. Are they for sale in Australia?

HS: Hi Helgies – Thanks Helgies! I believe it will be available in Australia shortly after the U.S. release. When I know for sure I’ll update the info on this page.

This is such an interesting topic, particularly at a time when it’s so easy to get an ebook immediately online. I sometimes get cookbooks electronically from the library, but if I really like the book having the physical book is the only satisfying way to use it – the heft of it, the colors, the font, the feel and color of the paper. I’m old, so in spite of your wonderful photography, I still love my cookbooks with drawings and I’m sorry that they’re going out of style. It used to bother me that I would get splotches of this and that on my beautiful books, but now I view them as a sign of a well-loved cookbook. Thank you for the tribute to the artisans who provide us with these treasures.

HS: I love illustrated cookbooks as well – nothing to be apologetic about. 🙂 And I think things go in phases. I’m excited to see a new generation of illustrated books emerging – so many beautiful, thoughtful ones. I’ll try to compile a list at some point. Might make for a good post here.

This was a really nice post, and I appreciate that you showed how much handwork is done even at the “industrial” scale of book production. I wanted to mention that there is a very vital community of book-making artisans in the San Francisco Bay Area, and if you ever want a tour and some introductions I’d be happy to set you up. Be forewarned: the book arts are seductive! I print books and work with several local binders on a smaller scale. And there are a couple shops that do the whole thing in house, printing to binding, for beautiful specialty hand-made books. BTW, I printed some notecards for you, via our mutual friend Chanda.

HS: Joel – I’ve heard so many nice things about you. And have been such a fan of your work from afar. I love my little QK notecards so much, and have sent them on to many destinations all over the world :). And I will absolutely take you up on your offer, maybe I can loop Chanda in too. I love the Center for the Book, and took an intensive letterpress course there a few years back (before it moved)…letterpress, not for the faint of heart. Hope to meet in person at some point soon.

This is such a great post. Being in communications and production I’ve visited quite a few printers and have seen the process evolve to digital. But so much is still manual. My uncle is a director of production for MoMA so he’s always traveling the world printing books in HongKong, Italy, Spain, etc. Plus, I find it so interesting to see the European printing machines and that the binding machine is Swiss 😉

Aloha Heidi, you bring this bookmaking process to life. You make it easy for your readers to feel the passion you have for book writing and bookmaking. Thanks for making Near and Far come to life as I imagine only you can. (Long time reader and supporter of your website and cook books.)

Heidi,

Your curiosity has taken us all on an amazing voyage of learning and understanding.

I look at the pictures of stacks of completed books and wonder which one is mine? Thank you for sharing the hands and faces of the artisans that create special things for us every day. Can’t wait for Sept 15!

Would that all authors took such interest in the process!

I worked in an offset print shop for years and it is amazing the hard work and talent that go into printing not just books, but anything really. Thank you so much for sharing this behind the scenes look at bookmaking. I believe if people understood the process more they would be more mindful of books and other printed materials – they are objects to be cherished; and not just for the words and pictures printed within them.

Oh my goodness I love this so much!! My favorite part of Mr. Roger’s Neighborhood was always the behind the scenes trips to factories (Crayons anyone?

and as a book lover, your photos are so fun to look through. So jealous that you got to tour the factory. The book looks beautiful and I can’t wait to see it!

oh my gosh heidi, this post is amazing. loved learning about this whole process — thanks for writing this! and hope you enjoyed your trip to hong kong xx

Great post about your book coming into being! Thanks you for taking the time to document your experience at the printer/book makers. I am so glad you enjoyed it. I worked a couple of years at a commercial printer and was amazed at the process and how much skill and hand work was needed on printed projects and books. Seeing it, and occasionally participating in the bindery work, was another educational experience, and very satisfying for me—I understood the “why” of what I had been taught and had learned as a graphic designer/illustrator.

Can’t wait to see your finished cookbook!

Much success with it,

Amy

Oh Heidi thank you for taking us on this journey. I’m waiting in anticipation to hold one in my very hands!

Reading this post was sheer delight, and I am even more excited to get my copy! Thank you for taking the time — it was a terrific learning experience.

Thanks for sharing! Such an inspiring process and more detailed than I would otherwise know. I can’t wait to see Near and Far in person.

Thanks for the fascinating post. Near and Far looks all the more gorgeous now!

Wow, what a journey and very humbling, indeed. So many hands and hearts go into a book. Thank you for these cookbook process posts. They are fantastic!

That was such an great post… its beautiful to see how things are made.

Loved the photos.

A fascinating perusal. Refreshing to see a glimpse of this mystery stretch of the bookmaking process. We all should be so lucky!

As someone who loves books I have to thank you for sharing this with us. How cool for you to travel to where your book is being printed to be able to watch the process. I wonder what the workers thought about your interest in what they might perceive as mundane job. Very interesting that you received a blank of your potential book so you would know in advance what the final version would feel like. The heft and feel of a book can make all the difference for me.

Interesting post on a fascinating process. Very best wishes in great success of Near & Far!

Hi Heidi, very fascinating, Abby@The Frosted Vegan said it best, as someone who loves books so much, as a cookbook collector I am very envious, thank you so much for sharing, all the best with your new, gorgeous piece of art, Sonja

Thanks for the tour—right up my alley. The book is beautiful. With your interests in craft and print, you might enjoy this tour I took of my dad’s offset shop in Chicago: http://mollyohalloran.com/special-printer-visit/

Thanks for sharing and highlighting the process — this is so neat!! It must feel great to know that your book was produced by artisans with pride for what they do.

So cool! I did press checks for a custom publisher for a few years and was always simply mind-boggled by the whole process. Print people are amazing and true trade- and crafts-persons. Can’t wait to hold your new book. It’s looks just perfect 🙂

I absolutely love that you are following the journey of your book from writing to editing to printing! I can tell how much heart and soul you put into it and absolutely cannot wait to have it in my hands.

Dear Heidi,

Thank you so much for this thoughtful and insightful series. I enjoyed this post specifically – though I’ve been through the writing and publishing process for a cookbook, I’ve never gotten to see or work on this very important step of creating the actual object. It’s fascinating to take a peek behind the scenes.

I cannot wait to cook from your new book!

Hi Heidi, again, another fascinating insight into the whole process of making a book – I feel I have learned a lot about books that I did not know. This post was particularly interesting and it is nice to have put a very human aspect to the printing process, something I had always assumed to be totally automated. So can’t wait for this book to be released!

Such an incredible journey. Good luck with all the oncoming success!

More Recipes

Weekly recipes and inspirations.

Popular Ingredients